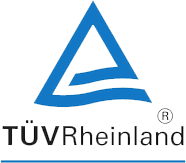

When designing a system, you want to guarantee the motor delivers the intended performance. Conditions and specifications ultimately dictate what type of motor best fits your needs when it comes to DC motors.

BLDC motors are growing in popularity thanks to their superiority in areas such as their ability to operate at high speeds, enhanced efficiency, and better heat dissipation. Additionally, they operate at increased performance levels in fields such as motor control technology.

Custom Brushless DC Motors Explained

A brushless DC motor, or BLDC motor, is a specific type of electric motor that does not have brushes or a commutator. DC motors are direct current motors and are considered electrical machines that transform electrical energy into mechanical energy. Brushless DC motors have ditched the mechanical commutation in place of electrical (a drive circuit or controller), eliminating the usual wear and tear mechanical motors endure.

The permanent magnets of a BLDC motor are on the rotor, while the electromagnets are on the stator. Compared to a brushed motor, these components are flipped inside out. A computer charges the electromagnets in order for the rotor to spin a full 360 degrees. Whereas brushed motors use the rotation of the motor itself to reverse the polarity of the coils, BLDC motors are actively controlled and function without many of the limitations of brushed motors.

Custom Brushless DC Motors Benefits

Brushless DC motors offer numerous benefits, including:

- High efficiency. Brushless motors are highly competent due to their synchronous operation (both their rotors and stators turn at the same frequency). The rotor is solely responsible for magnetic function, as it doesn’t require power. Due to their efficiency, BLDC motors offer decreased power consumption at the same power output compared to brushed motors.

- Low maintenance. Compared to brush motors, BLDC motors demand much less maintenance. Brushes must frequently be cleaned, ruling them out for use in many areas like the medical field.

- Long life. Because BLDC motors eliminate the use of brushes, they wear less quickly to ensure a longer service life.

- More torque. Another desirable feature of brushless motors is their ability to reach higher torques. Brushed DC motors cause friction, thus slowing down the motor. BLDC motors are free from this problem.

- Quiet operation. BLDC motors operate with far less audible noise than brushed DC motors.

- High speed. The lack of drag and associated heat buildup allows BLDC motors to reach the needed speed faster than brushed motors. They can run faster for longer periods of time and typically deliver more torque with the same power consumption.

- Less electromagnetic interference. BLDC motors produce less electromagnetic interference (EMI), making them well-suited for sensitive electronic equipment.

Applications of Custom Brushless DC Motors

Due to their many benefits, brushless DC motors are used across a diverse range of applications. They can accommodate various load and positioning requirements, and they are uniquely suitable for use in harsh environments.

Common applications of BLDC motors include:

- Medical devices. BLDC motors have a long service life and minimal maintenance requirements, making them a popular choice for medical devices.

- Industrial equipment. Their high torque and speed control make brushless DC motors a good choice for use in CNC machine tools, robotic systems, and other industrial equipment.

- Aerospace. Custom BLDC motors are resistant to shock and other harsh environmental elements. This, along with their compact and durable design, makes them ideal for various aerospace applications, including satellites, drones, and more.

- Military and Defense. The durability and long lifespan of BLDC motors make them a good choice for several military and defense applications, including radar systems, robotic systems, unmanned vehicles, and more.

- Automotive manufacturers. Automotive manufacturers use BLDC motors due to their higher efficiency and torque. Common uses include electric vehicles, electric bicycles, and hybrid vehicles.

- Home appliances. BLDC motors can often be found in home appliances such as refrigerators, HVAC systems, washers and dryers, and compressors. They are also increasingly being used in electric fans.

- Commercial electrical products. BLDC motors are used to control the propellers and gimbal in drones, feed paper into laser printers, and power electric tools.

- Fans, pumps, and blowers. Brushless motors are used to power fans, pumps, and blowers in air cleaners and other air conditioning systems.

Custom Brushless DC Motors from Composite Motors

Brushless DC motors offer several advantages over their brushed counterparts, making them a preferred choice in numerous applications and industries. At CMI, we can deliver custom, USA-made BLDC motors that meet your unique needs while ensuring long-lasting, durable performance. For more information about our BLDC motors and other products, contact CMI today.

To learn more about our unique solutions get in touch with one of our experts to find out how we can serve you.